Overview

I. Product Specification:

|

ITEM |

Cotton Waffle Towel |

|

Material |

100%cotton towel 34x75cm |

|

Size available |

napkin towel: 24x24, 26x26, 28x28, 27x27, 30x30 hand towel 30x37, 30x47 bath towel:40x80,40x82, 33x73, 34x75, 38x78 , 34x84, 34x86, 35x85.... bath towel 50x100, 60x120, 65x130, 70x140, 90x150... beach towel 150x200 cm |

|

Color |

pantone color selectable,plain dyed |

|

Weight/thickness |

Depend on your require |

|

Technic |

herringbone dobby border |

|

Features |

high absorbency&beautiful&convenient,high quality with luxurious and fashinable flower designs |

|

Additional technic |

embroidery |

|

MOQ |

500kg/item,negotiable |

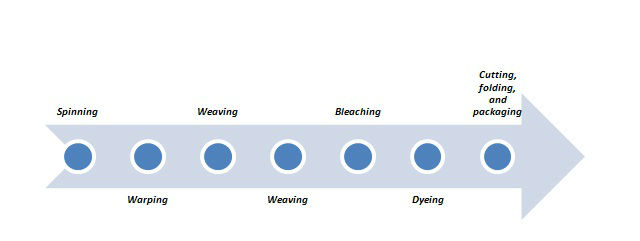

II. The Manufacturing Process:

III. Quality Control:

Towels are rigorously checked for quality control throughout the production process. If yarn is purchased, it is randomly checked for weight and must be the standard established by the company (lighter yarn spools indicate the yarn is thinner than desired and may not make as sturdy toweling). Bleach and dye vats are periodically checked for appropriate chemical constitution.

During the weaving process, some companies pass the cloth over a lighted inspection table. Here the weavers and quality inspectors monitor the towel for weaving imperfections. Slightly unevenly woven towels may be straightened out and touched up. But those that cannot may be labeled "seconds" or imperfect or completely rejected by the company. As in all aspects of the process, visual checks are a key to quality control—all involved in the process understand minimum standards and monitor the product at all times.

IV. Product Application:

Tan Phuong Textile Company Limited

Thôn Phương La, Xã Thái Phương - Huyện Hưng Hà - Thái Bình

Việt Nam