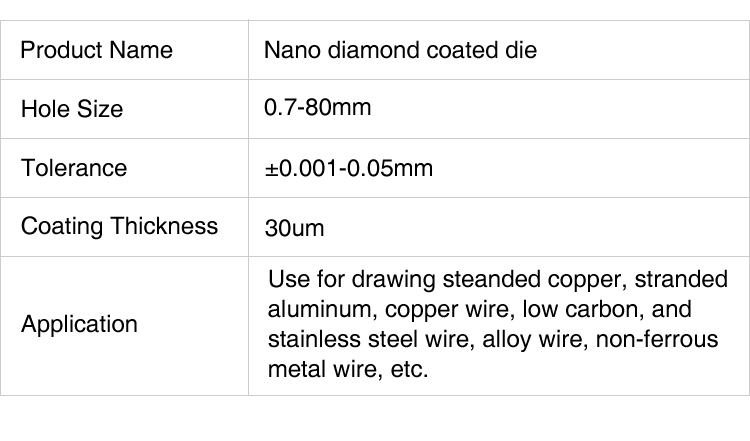

Product Details

Nano-diamond coating mold:

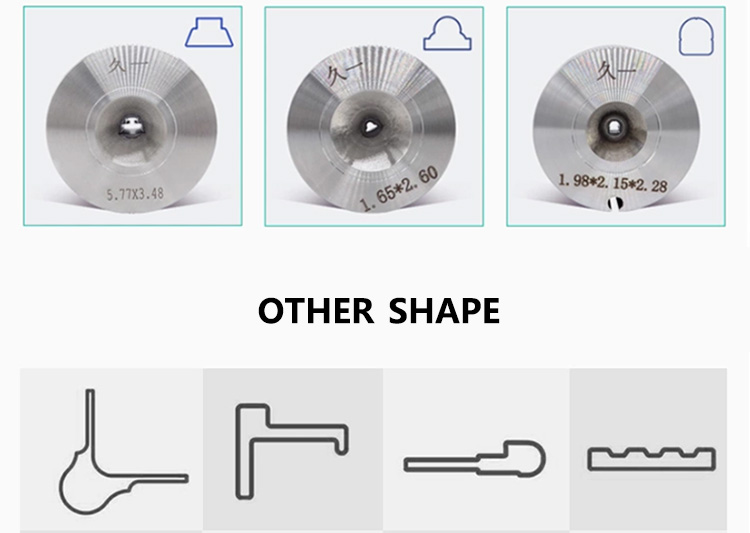

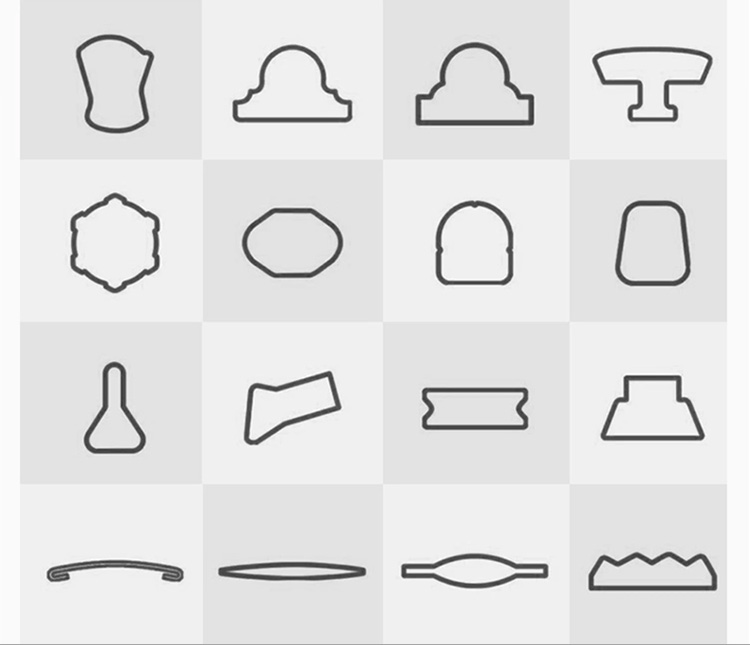

It uses cemented carbide (WC-Co) as the substrate, uses chemical vapor deposition (CVD) to grow a layer of diamond film on the surface of the inner hole of the mold, and the diamond coating is precisely ground and polished to obtain a new mold. The product has The toughness of the cemented carbide mold, the hardness and wear resistance of natural diamond, the bright inner hole, the low friction coefficient, and the long service life. The mold inner diameter production range is 0.5mm-50mm.Can process and customize various materials and sizes of wire drawing dies.

Advantages of nano-diamond coating mold: 1. Long service life: The service life of drawn copper aluminum wire, low carbon steel wire, medium carbon steel wire, cable stranded wire, welding wire and mold is more than 20-30 times that of cemented carbide molds, and cable stranded wire is 50 times that of cemented carbide. above. 2. The size control precision is high, the wire size is stable, and the size consistency can be maintained for a long time. 3. The inner hole of the mold is bright, self-lubricating, and the surface friction coefficient is small. The produced wire has a high surface finish, non-sticky, and the finished wire is of good quality. At the same time, it can reduce equipment loss. 4. It saves raw materials, and the length of the metal wire produced is 1%-2% longer than that produced by traditional molds. 5. Repair-free mode, maintenance-free, reducing the number of shutdown inspections and mold changes, greatly improving production efficiency, significantly increasing output per unit time, and saving a lot of labor costs. 6. It is suitable for the pickling-free drawing process, which is environmentally friendly and energy-saving.

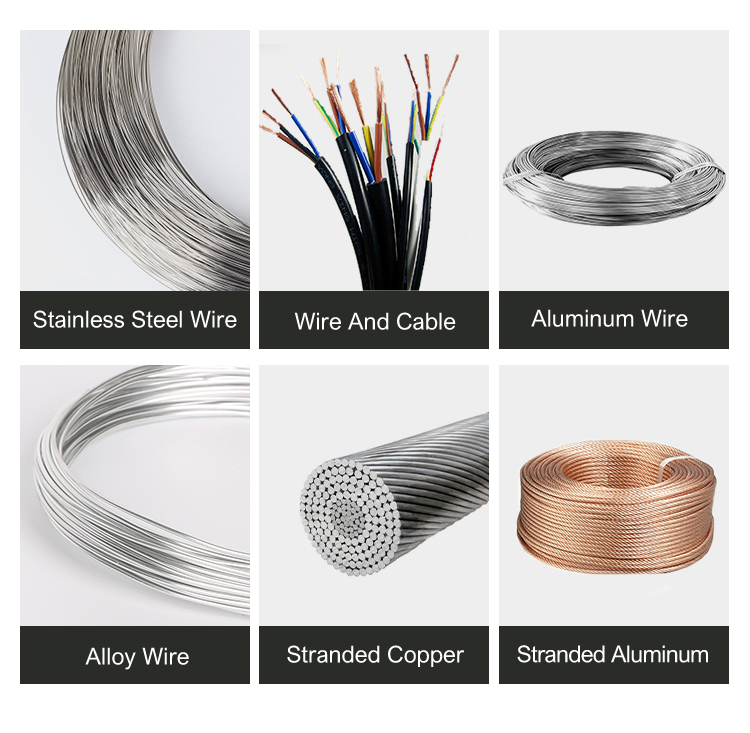

Application areas: Copper wire, aluminum wire, wire and cable, stainless steel welding wire, medium and low carbon steel welding wire, stainless steel wire, low carbon steel wire, copper tube, aluminum tube, stainless steel tube, etc.

Why choose us?

Long history, Rich experience

Since 1990, we have more over 30 years history, and have accumulated much experience on copper bus bar drawing carbide die manufacturer and production.

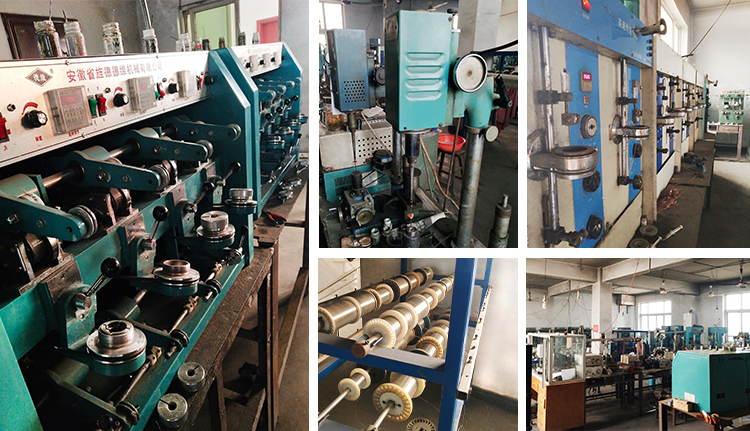

Large scale, Standard center

Our company occupies 200 acres and the total plant area is more than 70,000 square meters, including eight standard workshops, one office building and one research building. It is also a provincial engineering technology center..

Good service, High quality

We have professional service team. Not only can we help you receive diamond wire drawing dies apply for die blanks for wire drawing, but also supply more friendly and warm service for you.

Many certificates, Professional study

We have receiced many national and local awards patent certificate and obtaining many invention patents. and has an independent research and development organization in cooperation with Henan University of Technology and Zhengzhou University.

International famous, Powerful advantage

Wire drawing dies for copper wire, gold wire, silver wire, aluminum wire, and brass bar, etc, which are exported to more than 200 countries and regions. And the company participates in domestic and international exhibitions many times.