Product Description

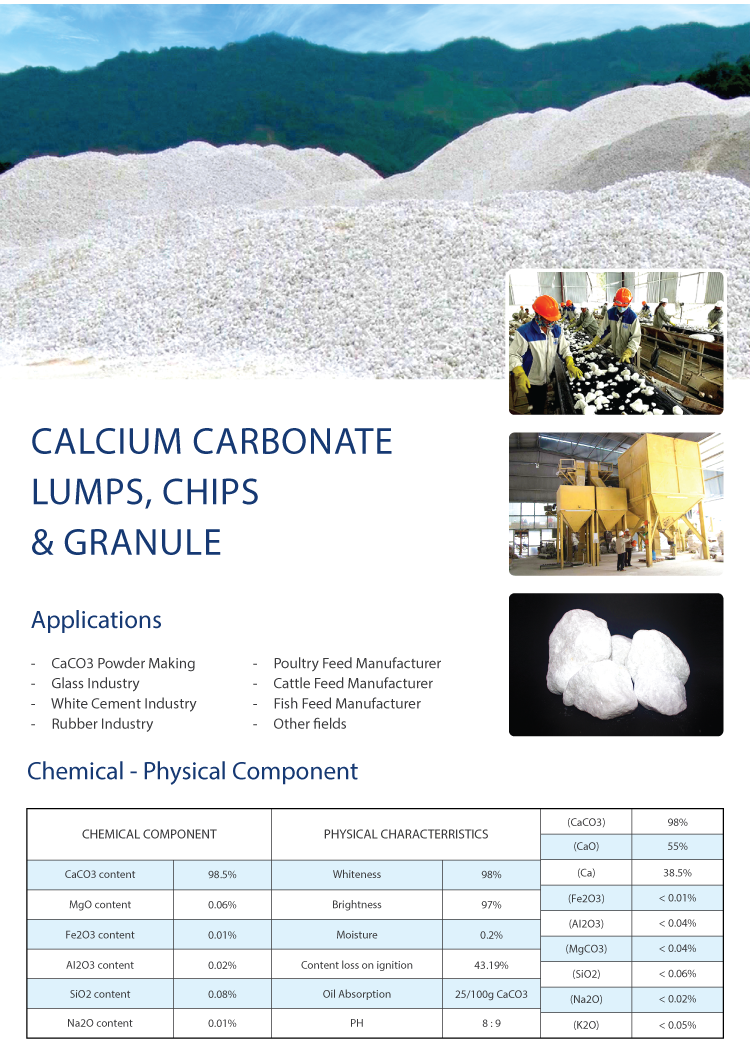

LIMESTONE/ CALCITE/CACO3/ MARBLE

Limestone is a type of sedimentary rock, mainly composed of calcite (calcium carbonate CaCO3). Limestone is rarely in pure form, but it is often mixed with impurities such as silicon slate, silica and igneous rocks as well as clay, mud and sand, bitumen … So

it has the color from white to ash, light blue, gold and dark pink, black. Limestone has hardness 3, volume of 2600 ÷ 2800 kg /

m3, compressive strength 1700 ÷ 2600kg / cm2, water absorption 0.2 ÷ 0.5%. Silica limestone is more intense, but brittle and hard.

Dolomite limestone has better mechanical properties than regular limestone. Limestone contains much clay (greater than 3%), the

water resistance is poor. Limestone is not as solid as granite, but is more common, more easily exploited and processed, so it is

more widely used. Limestone is often used as aggregate for concrete, for pavement of cars, railroads, and for general irrigation

projects, as well as for manufacturing cladding, paving and architectural structures. other. Limestone is the raw material for

lime and cement production.

Company Profile

ABOUT US

Pha Le Plastics Manufacturing – Technology Joint Stock Company (formerly known as Pha Le Mineral Joint Stock Company) was established in 2008. Starting from a small mining plant, the company has grown into an enterprise with Hanoi is a fully-fledged language-based website with two strategic branches in the port city of Hai Phong and Nghe An. Currently, Pha Le owns 5 mineral mines: 2 Granite quarries in Ninh Thuan, 3 white marble quarries in Nghe An and especially CaCO3 quarries in Thung Hung and Quy Hop mountains with an area of over 10 hectares. This quarry is rated as one of the best quality marble sources in the world in terms of brightness and whiteness with abundant reserves of up to 5,000,000 m3. With the available raw materials, in the past 8 years, Pha Le Plastics has focused on investing in the most advanced exploitation methods, especially processing technology, to be able to proactively manage product quality in a good way. most to meet the domestic and international market with output from 300,000 to 500,000 tons a year. Grasping the information of preferential policies of the State, Pha Le Plastics has built its factory and production facilities in a strategic location: Dinh Vu Port Industrial Park, Hai Phong, where the The company has been granted a construction license for CaCO3 superfine powder factory and other products such as Taical fillers and packaging, etc. The annual output of super fine CaCO3 powder reaches 150,000 to 200,000 tons. The biggest competitive advantage of Pha Le Plastics is its position, which facilitates the transportation of goods from the factory to the port, helping to minimize costs and time. Other companies in the same manufacturing sector would normally be affected by regulations related to vehicle load control and geographical distance, which would affect product prices. Thanks to the maintenance of an excellent staff and the best logistics model. Pha Le Plastics has succeeded in keeping prices competitive but still produces high quality products with accurate delivery times to customers.

Our Advantages

As the owner of the largest CaCO3 quarry in Quy Hop, Nghe An with a total exploiting area of 5.2 hectares along with all production facilities.

The first and only company with a comprehensive business model from raw material exploitation to the final product.

Master the most advanced mining and processing technology in the country.

Having large capacity: 8,000 to 10,000 tons of powder and 10,000 tons of plastic padded products per month.

The factory in Hai Phong covers an area of 2 hectares, with 4 flour production lines and 6 filler production lines.

Production facilities supported by convenient logistics system and good infrastructure, located near Hai Phong port (2km away) and close to Ha Noi - Hai Phong expressway.

Our Facilities

At Pha Le Plastics facilities, we follow ISO standards, as well as lean manufacturing to achieve the best efficiency for our production processes and to create the best working environment for our team members.

Exhibition

Chinaplas 2019 is the largest Plastic & Rubber Trade Fair in China and Asia.

ARABPLAST 2019 – International trade fair for plastic, petrochemical and rubber with the presence of 1000 exhibitors in Dubai.

VietnamPlas & VietnamRubber 2018 – International Exhibition of Plastics Industry in HCMC.

Plastics INDIA 2018 – International exhibition of plastics industry.

Bangladesh 2018 – 13th International Fair.

CHINAPLAS 2017 – Asia’s leading international trade fair for plastic & rubber.

Pha Le Plastics Manufacturing And Technology Joint Stock Company

2nd floor, Building A, Rivera Park, No 69 Vu Trong Phung Street - Thanh Xuan - Hà Nội

Việt Nam