Overview

Product Description

GENERAL DESCRIPTION

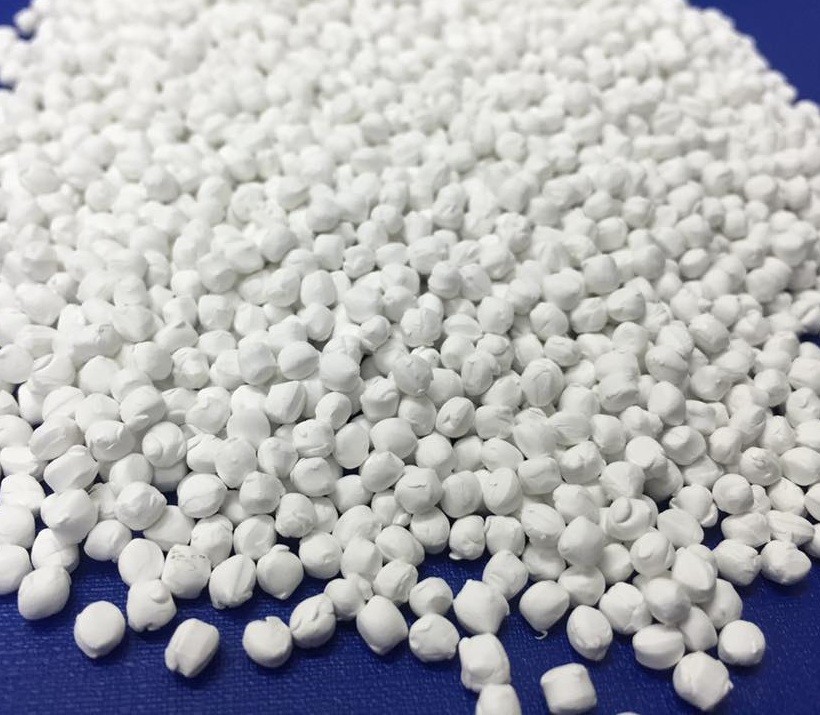

PP filler masterbatch is a polyethylene based master batch containing (depends on each grade) from 75~88% calcium carbonate. It is grayish white with excellent sensibility.

It can be mixed with polyethylene resin for film blowing, casting, extrusion and is easy to disperse with compatibility. It functions as a modifier to improve the heat resistance, slip resistance, size stability and printability. It also reduces heat release from burning and therefore prevent further environmental pollution.

Applications

1. PP NON WOVEN

2. PP injection molding.

3. PP WOVEN BAG

It can improve machine's extrusion efficiency and increase film & physical properties

Physical properties

The below table:

|

Specification |

Test method |

Unit |

Min |

Max |

Result |

|

Resin |

--- |

--- |

PP |

||

|

Mix content |

--- |

%wt |

75~88 |

||

|

Particle size |

Malvern Mastersizer 2000 |

µm |

2.99 |

3.01 |

2 |

|

MI @2.16kg/190oC |

ASTMD1238 |

g/10mins |

3 |

4 |

11.8 |

|

Density |

ASTM D1505 |

g/cm3 |

1.65 |

1.67 |

1.68 |

|

Moisture |

ASTM D644 |

% |

0.08 |

0.1 |

0.08 |

|

Shape |

--- |

granule |

2.7x2.7 mmФ |

3.1x3.1 mmФ |

3x3 mmФ |

Packing & Delivery

1. Packing: 25kg/PP bag or 1000~1250kg/jumbo bag.

2. Note to avoid moisture, insulation and breakage in transportation.

3. The product is sensitive to moisture. No problem to store in original packing bags. Make sure to use product immediately after opening the packing bags. If it has moisture problem, dry by hot air recycle machine under 90oC for 30 minutes.

Our Company