Overview

Essential details

Warranty: 5 years

After-sale Service: Online technical support, NONE

Project Solution Capability: graphic design

Application: Hotel, For steel structure and concreting work

Design Style: Modern

Place of Origin: Tien Giang, Vietnam

Brand Name: DHN COMPANY

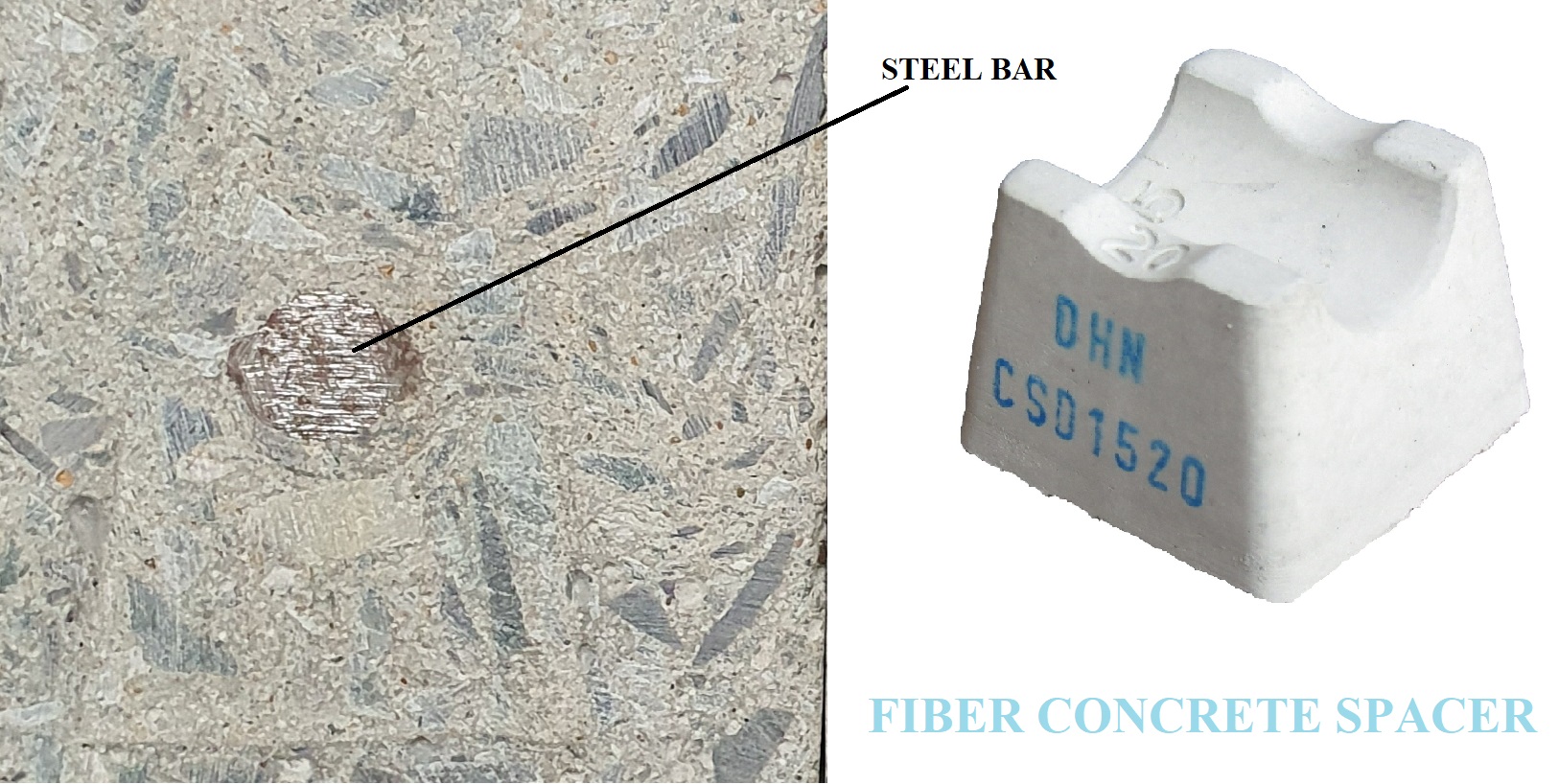

Model Number: CSD1520

Type: cover size 15/20mm in slab, Double size (15mm and 20mm)

Product name: Rebar spacer or concrete cover spacer

Model type: CSD1520

Material: Hight strength Concrete with fiber

Main Materials: Sand, stone, cement, adtitive, fiber glass, water

Usage: used for Slab, wall, column, foundation, precast

Certificate: Braking load 6 KN

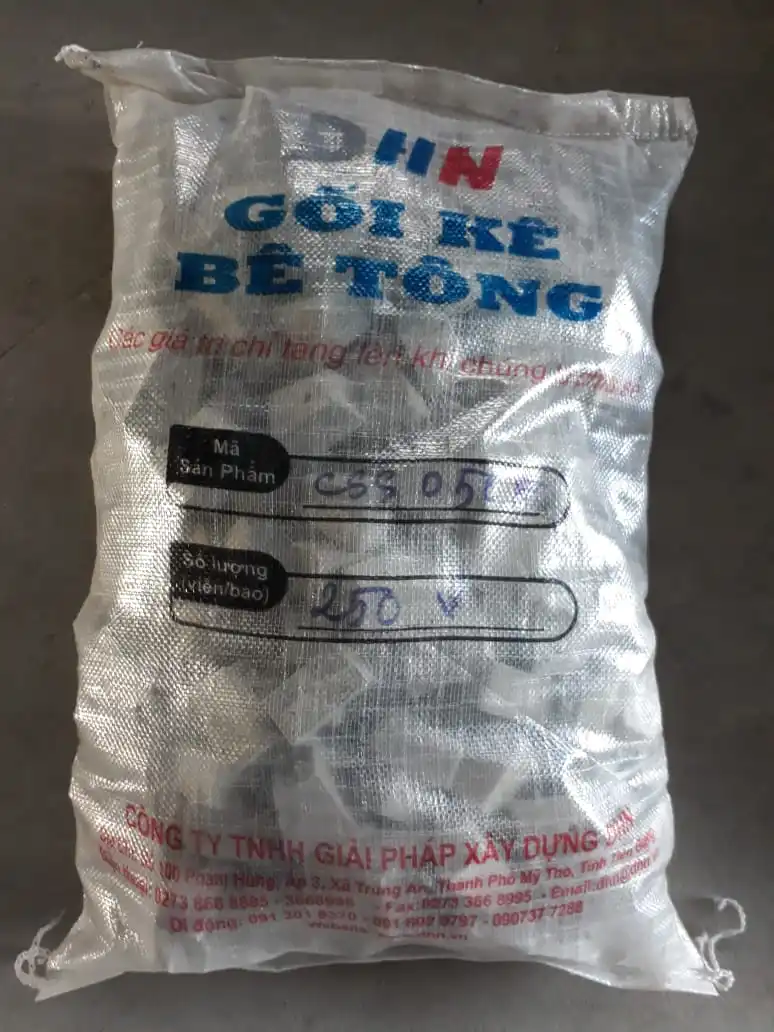

Packing: 100 - 1000 pcs/ plastic woven bag

Delivery time: 15-25 Days

Supply Ability

Supply Ability: 1000000 Piece/Pieces per Month

Packaging & delivery

Packaging Details

- 100 - 200 pcs / plastic woven bag

Port: Cat Lai port

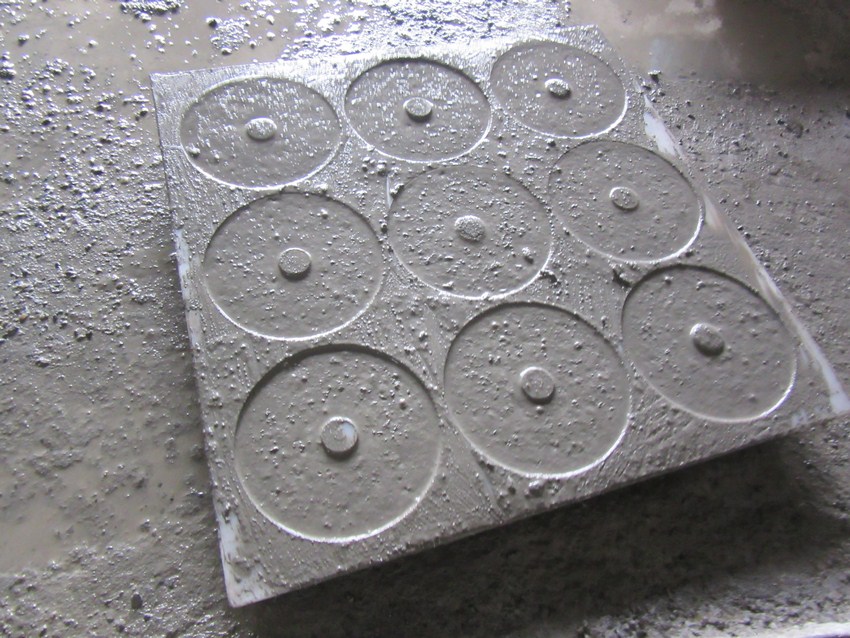

Picture Example:

Lead time:

| Quantity(pieces) | 1 - 100000 | >100000 |

| Lead time (days) | 7 | To be negotiated |

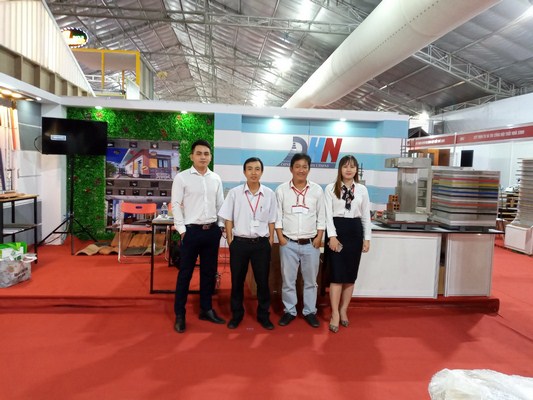

Company Profile

DHN CONSTRUCTION SOLUTION COMPANY LIMITED

DHN Construction Solution Company was established in 2011. The scope of activities is to provide construction products and solutions. Young and energetic members working together with creative minds are the key to success for DHN in the past 10 years. DHN is a reputable product supplier in Vietnam for the following products: - Fiber Concrete Spacer for Column Beam, Slab, Foundation, ...

- uPVC Plaster Bead, uPVC Tile Trim, uPVC Groove Joint

- Stainless Tile Trim, Stainless steel U, T, V profile

- Galvanized expanded Metal Lath, Galvanized Coil Lath,....

We are improving to be a well-suited and friendly partner to corporate with and believe in. "Why do we make it better? Because we love it." - We are sincerely welcome you to contact us for business.

Production Department

- Management: Quality management and experience

- Engineer: Experienced, young, creative.

- Workers: diligent, enthusiastic and eager to learn

Sales Department

- Management: Understand the market, much experience

- Staff: Good at communication, enthusiastic, hardworking

- Warranty:diligent, enthusiastic and honest

Products Description

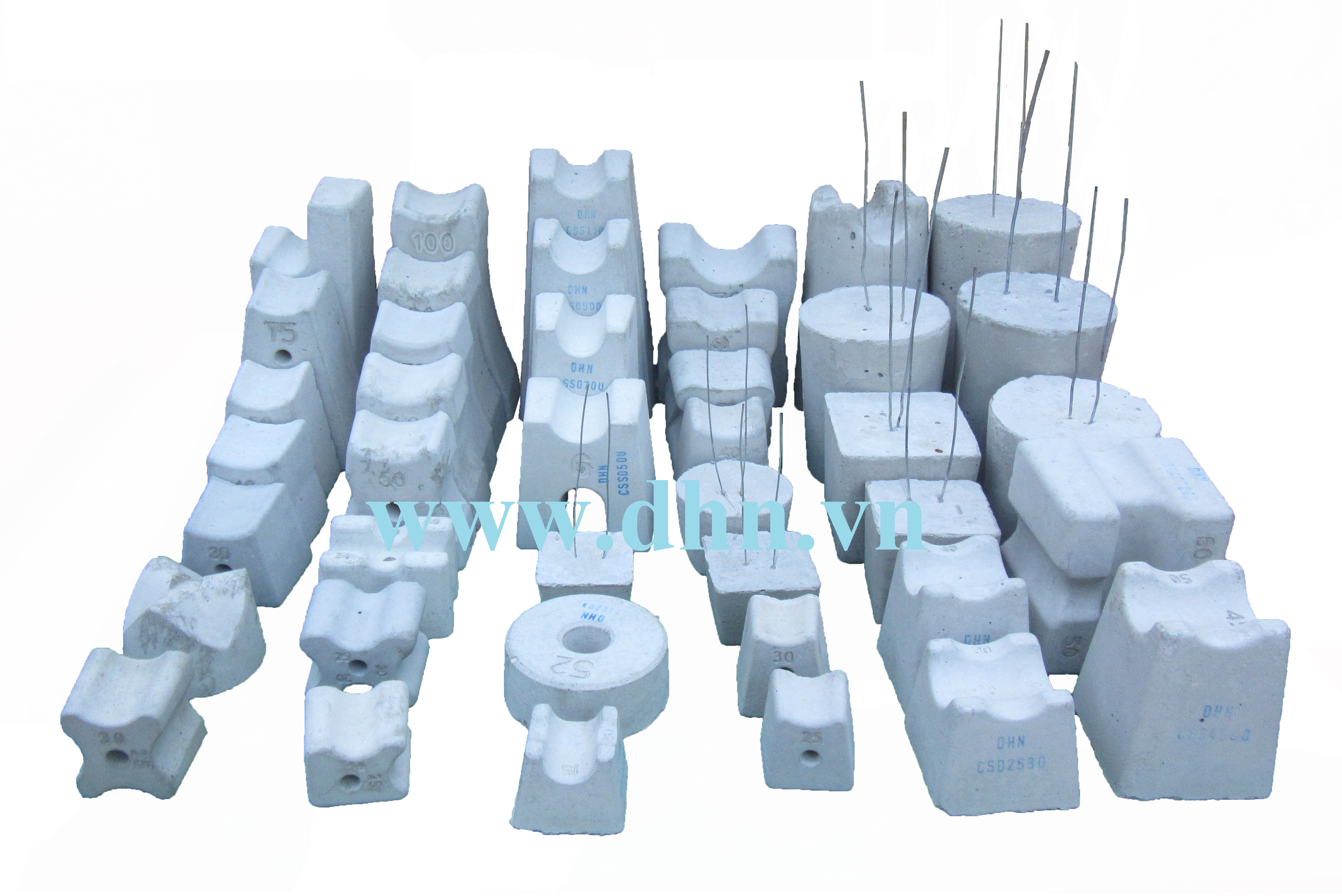

Rebar Spacer and Cast concrete spacer

A re-bar spacer is a device that secures the reinforcing steel or "re-bar" in reinforced concrete structures as the re-bar is assembled in place prior to the final concrete pour. The spacers are left in place for the pour to keep the reinforcing in place,and become a permanent part of the structure.

Cast Concrete Spacers ensure that the specified concrete cover to the reinforcement for structures and structural elements is achieved, both before and during concreting. Concrete Spacers are mainly used for the walls, columns and foundations.

Point Concrete Spacer

- Single size concrete spacer

- Multi size concrete spacer

- Concrete spacer with wire

Circular Concrete Spacer

Circular Concrete spacers are designed and manufactured from quality concrete, for strength and stability.

Bar Concrete Spacer

- Concrete spacer square bar

- Concrete spacer triangle bar

- Concrete spacer C, snake, banana profiles

Function of Re-bar Spacer (cover block):

The engineering study of every reinforced concrete construction, whether it is a building, a bridge, a bearing wall or other

structure, predicts the positioning of steel re-bars at specific positions in the volume of concrete (predicted concrete cover of steel reinforcement bars). This cover typically varies between 10 and 100 mm. The statics of every concrete construction are designed in such a way that steel and concrete properties are combined in order to achieve the maximum possible strength for the particular construction (e.g. anti-earthquake protection) as well as to prevent the long-term corrosion of steel that would weaken the construction. Re-bar spacers secure the correct position of steel, thus assisting in the practical application of the theoretical specifications of concrete construction. The cover of the steel of a particular construction element (for example in a concrete slab or a beam) should be generally uniform within the element.

The use of spacers is particularly important in areas with high earthquake activity in combination with corrosive environment (like proximity to salt water of sea)

Why are concrete spacer better than plastic spacer?

Plastic spacers and bar supports do not bond well with concrete, therefore they are NOT compatible materials. Much of this compatibility is explained through a single phrase :

- Plastic has mechanical (holds the bar in position) but NO structural properties (always will remain a foreign element within the construction). But why is that? Well here is a detailed explanation of this affirmation: When the concrete is poured into the form, a small gap is created between it and the plastic. Plastic has a coefficient of thermal expansion and contraction 10 to 15 times that of concrete, and when subjected to temperature variations, the plastic continues to expand and contract at that higher coefficient. At high temperatures, plastic can even melt. The result is a separation between the spacers and the poured concrete, creating a free passage for corrosive agents to reach the steel reinforcement from the exterior of the concrete product. This will cause the steel and eventually the concrete to corrode. If steam curing is applied to the concrete, the heat in the curing process causes the plastic to expand while the concrete is relatively fresh and weak. After reaching the maximum curing temperature and volume expansion of the plastic, the temperature is held at this level until the concrete reaches the desired strength. After curing, the subsequent lower temperatures cause the plastic to contract, and a gap remains at the interface between the plastic and concrete.

- Plastic spacers are also subject to corrosion when they come into contact with chlorides and chemicals, where concrete has a much higher resistance.

- Concrete spacers and bar supports are made of the same material as the poured concrete, so thermal expansion and contraction are equal. And because they are the same material, the concrete and spacers will bond. No gaps!

- Concrete spacers and bar supports help maintain material integrity and uniformity of the concrete, and provide a cover over the reinforcement that protects against corrosion.

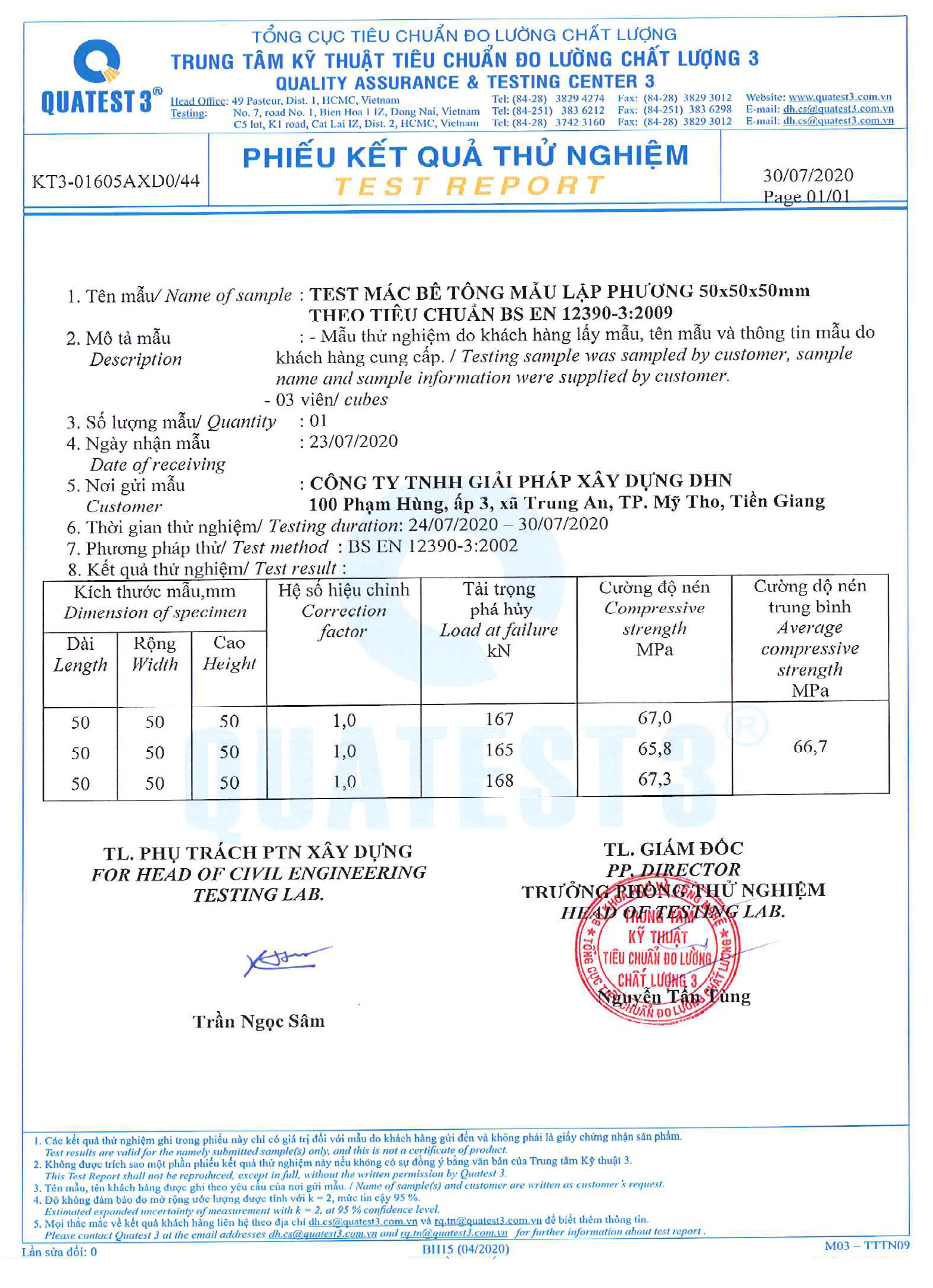

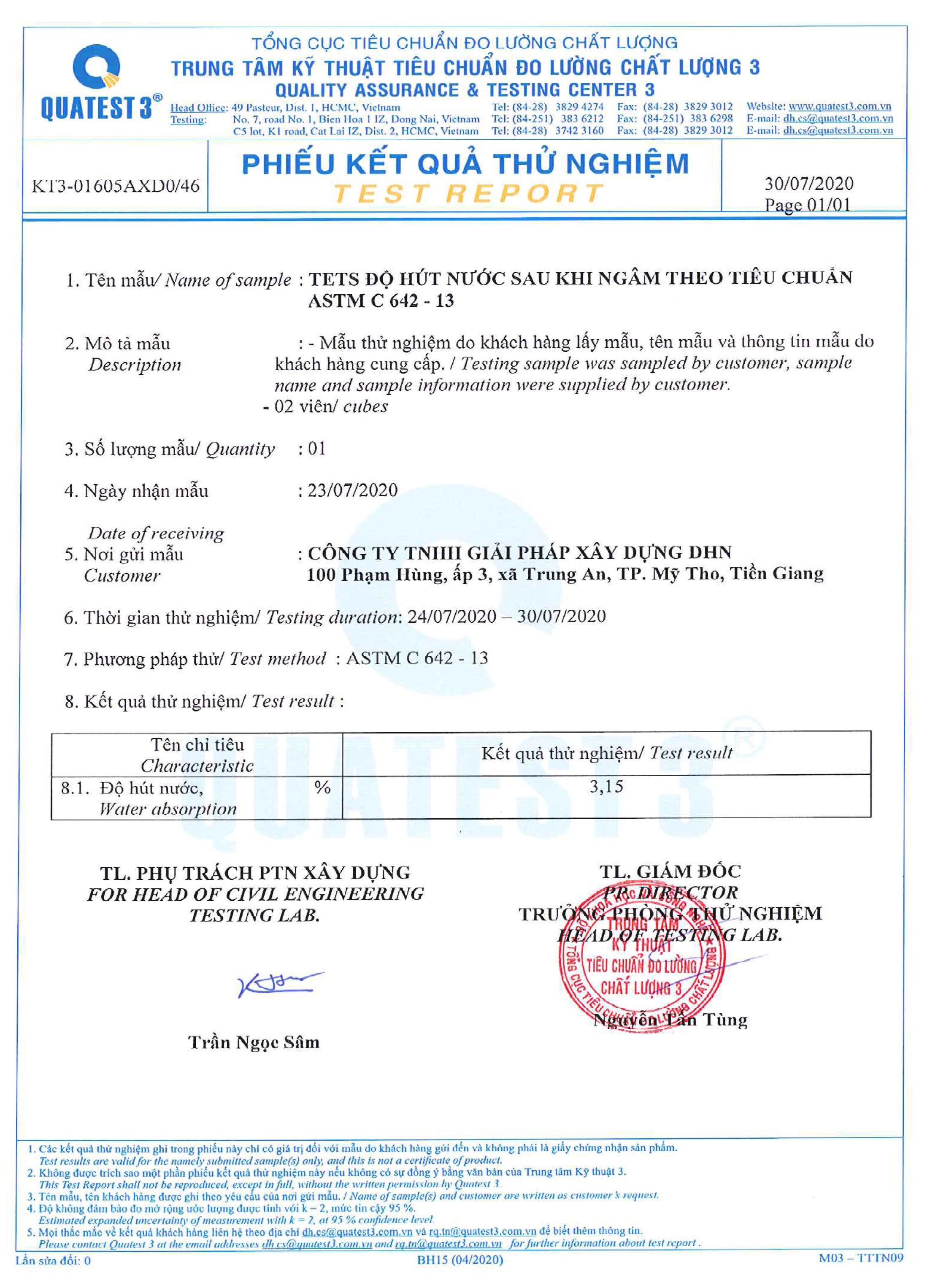

Hight Compressive Strength

- Size of cubic test : 50x50x50 mm

- Test method: compressive strength BS EN 12390-3:2009

- Compressive Strength: 66.7 MPa

Water Absorption

- Size of cubic test : 50x50x50 mm

- Test method: Water Absorption ASTM C642-13

- Water absorption result: 3.15%

Manufacturing Process

1. Raw material

2. Additives

3. Clean Mould before use

4. Quantitive raw material

5. Mixer

6. Concrete test before use

7. Concreting with mold

8. Concrete curing

9. Remove product out of mold

10. Concrete strength test

11. Packaging

12. Load on container

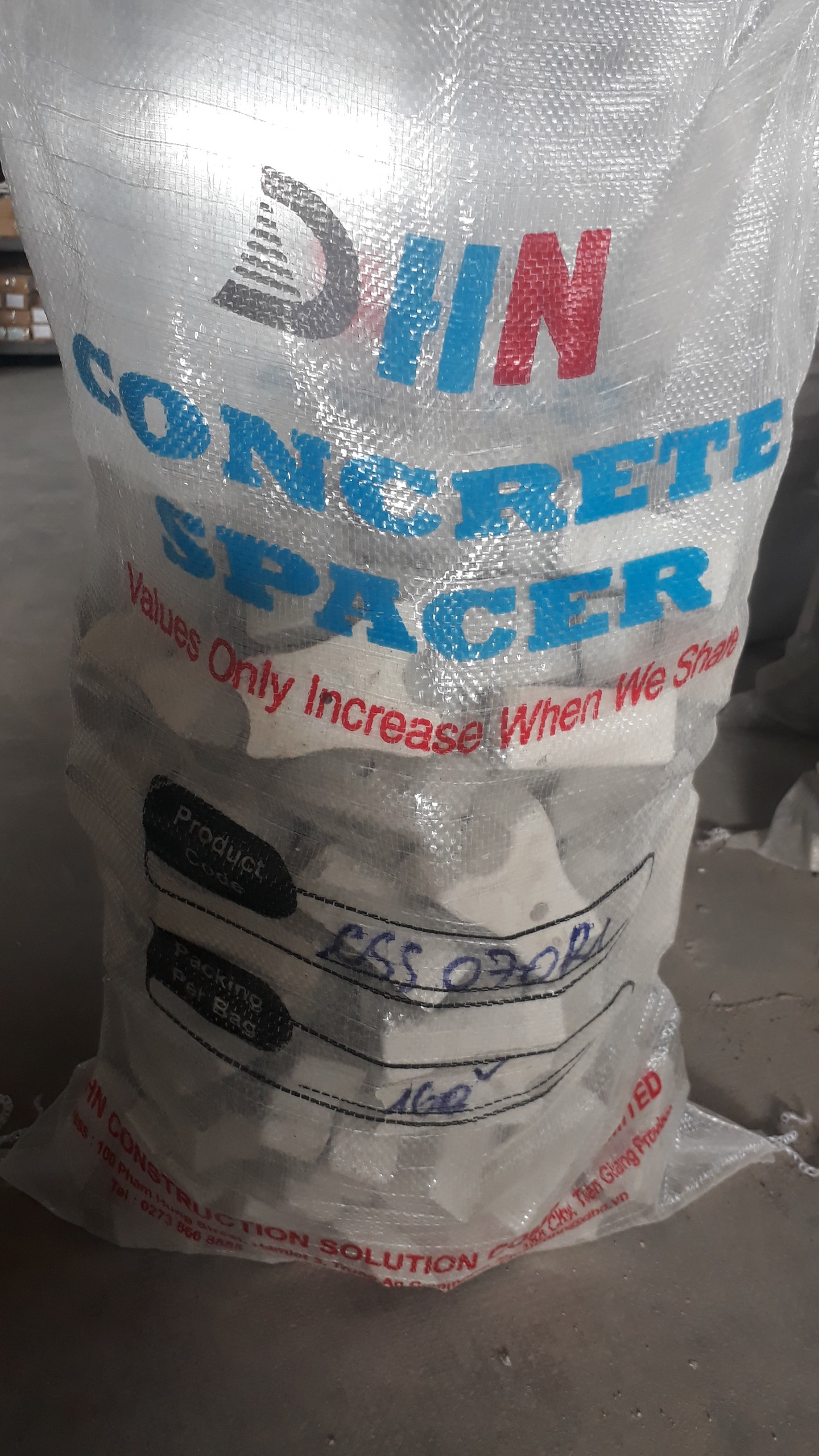

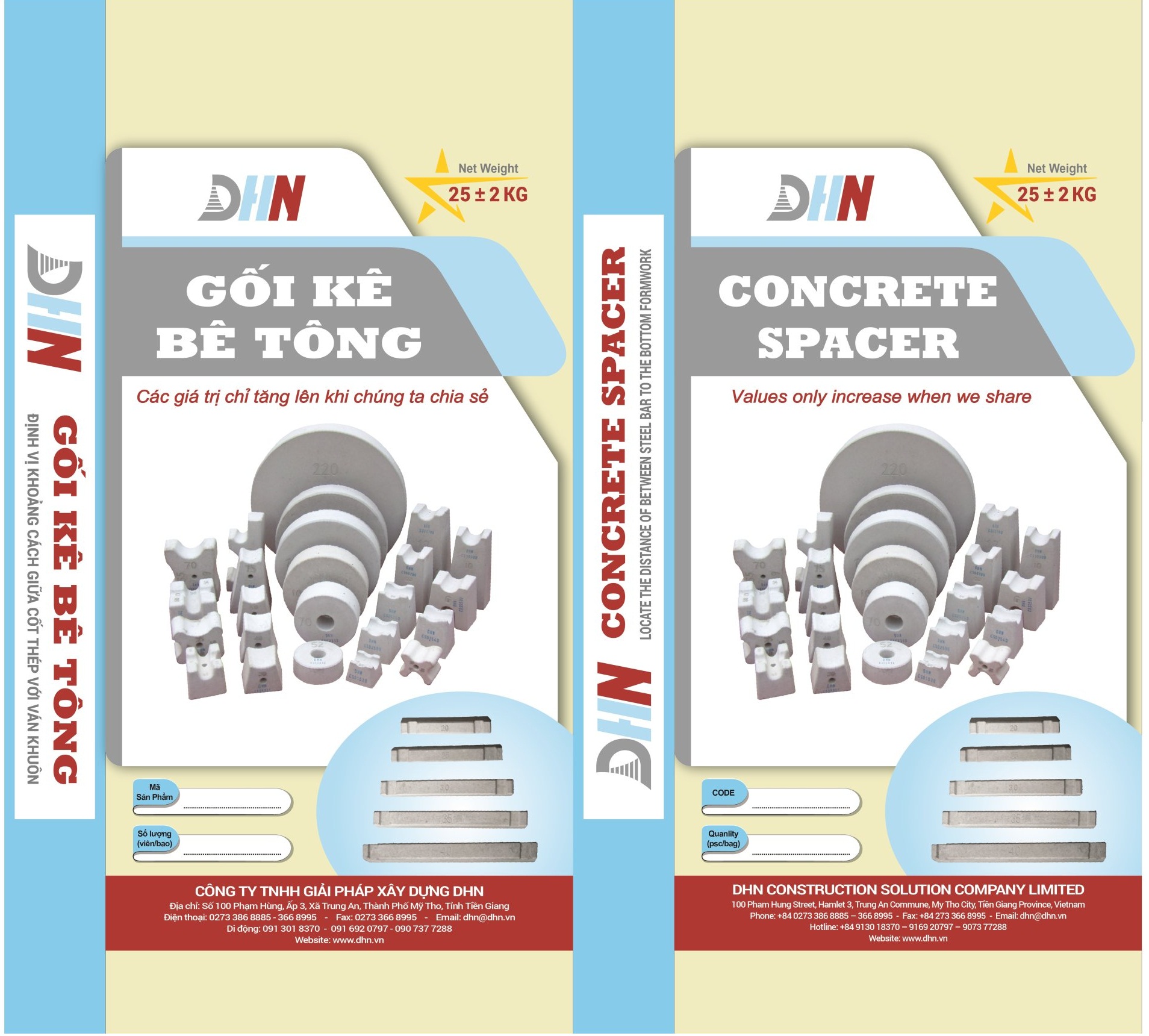

Product packaging

PP Plastic Woven bag

- Quantity : standard or customized

- Quality of bag: flexible, not punctured, not torn

Design logo on bag

- Size, Logo and color of bag: standard or can be customized

Inventory

- Fast delivery time

- Wood Pallet

- PP plastic strapping

Exhibition

Vietbuild Internaltional Exhibition 6/2019 in HCM City, VietNam

- Interior & exterior Architecture Decoration

- New Material and solutions for construction works - Real estate

Vietbuild Internaltional Exhibition 11/2019 in HCM City, VietNam

- Interior & exterior Architecture Decoration

- New Material and solutions for construction works - Real estate

Vietbuild Internaltional Exhibition 12/2019 in HCM City, VietNam

- Interior & exterior Architecture Decoration

- New Material and solutions for construction works - Real estate

Installation Instructions

Single size concrete spacer for slab (staggered steel)

Sing size concrete spacer for slab (parallel steel)

Double size concrete spacer for slab

Muiti size Concrete spacer for slab (parallel steel)

Why Choose Us

High quality with fiber glass

- Best material: cement, sand, stone.

- Best cement additive.

- Best mixer machine.

- Standard Production process.

Competitive Price

- Best price for partner.

- Cheaper local charge for shipment.

- Maximum loading.

- Documentation is full and quickly

Fast Delivery & Good service

- 10-15 day for delivery

- Good after sales support

- Support technical service

- Online 24/24 for FAQ